Battery charging problems sometimes arise. Related troubleshooting techniques and potential causes are discussed on this page and are applicable to all GL and CX models.

Testing The Charging System

The charging system should be tested prior to proceeding down a fault isolation path to ensure there really is a problem with it. This sounds obvious, but it's surprising how many times a charging system is deemed faulty simply because the battery runs down. The battery may be running down for other reasons, such as some newly installed gadget that places a small but constant load on the battery or perhaps a malfunction elsewhere in the electrical system.

The charging system health can be assessed by making two simple battery voltage measurements. (The procedure for measuring the battery voltage was previously described in the multimeter section.) First, measure the battery voltage with the ignition switch off (i.e. no load). It should be around 12 Volts. Next, start the bike and run the engine at about 2000 rpm and measure the battery voltage again.

If the battery voltage decreased, this indicates the battery is discharging under the electrical load of the bike and the charging circuit is not working.

If the battery voltage increased slightly but never rose higher than 14 Volts, the charging circuit is working but at reduced capacity or is overloaded. There is likely a problem that needs correction.

If the battery voltage increased to at least 14.2 Volts but not over 14.8 Volts, the charging circuit is working properly. On most bikes the charging voltage runs about 14.5 Volts.

If the battery voltage increased to above 14.8 Volts, the charging circuit is likely overcharging the battery. Again, this problem needs correction. For the GL500, one very common cause of this is a poor ground connection under the rider's seat, see here.

The Battery

It's possible for the battery itself to be the cause of a charging system problem even if it is new. It should be replaced if there is any question about its health because the charging system will not operate properly without a good battery installed. Among other functions, it stabilizes the charging system voltage.

One battery failure mode is for it to simply not hold a charge. This happens most often when the battery has some age on it, even more so if used infrequently. Check the battery voltage both with the ignition switch off and while cranking the engine.

With the ignition switch off (no load), the battery voltage should be 12 Volts or slightly higher. When cranking, it should not drop below 10.8 Volts or so. If this happens, the battery is probably defective or discharged. If the battery cables get really hot while cranking, another possibility is a serious engine problem where it is binding when turning over.

If the no-load battery voltage is less than 10.5 Volts there is a chance it has a shorted cell. When this happens, the battery cannot be charged to greater than 11.5 Volts or so. It may reach this value or higher with a charger connected, but the voltage will rapidly drop to a much lower value within a few minutes of disconnecting the charger. This failure mode is less common but does happen on occasion.

On a related topic, sometimes it may be necessary to jump the battery to start the bike. A 12 Volt car battery can be safely used for this purpose, whether installed in a car or not. However, I do not think it is a good idea for the car engine to be running when doing so. Significant high voltage transients can result from the car's charging system, particularly when subjected to intermittent high current loads. Although this occurrence is unlikely, especially with modern vehicle electrical systems, it is an unnecessary risk.

The Stator Connector

The stator connector is the connector with three yellow wires. This is where

the alternator stator (located inside the engine) is connected to the

regulator/rectifier module (located under the battery tray on GL bikes).

The stator connector has a long history of problems on many Honda bike models. In addition to charging problems, fires have started when this connector has malfunctioned. I'm aware of one CX turbo bike that was completely destroyed by fire when this connector failed.

This particular stator connector shows evidence of arcing and severe

overheating. Thanks go to Honda CX500 and

GL500 Forum member Dave from Slippery Rock for sharing this example.

Unplug the connector and closely inspect both halves for evidence of overheating, arcing, corrosion, and broken or frayed wire ends. A good solid electrical connection is absolutely essential here for all three wire junctions.

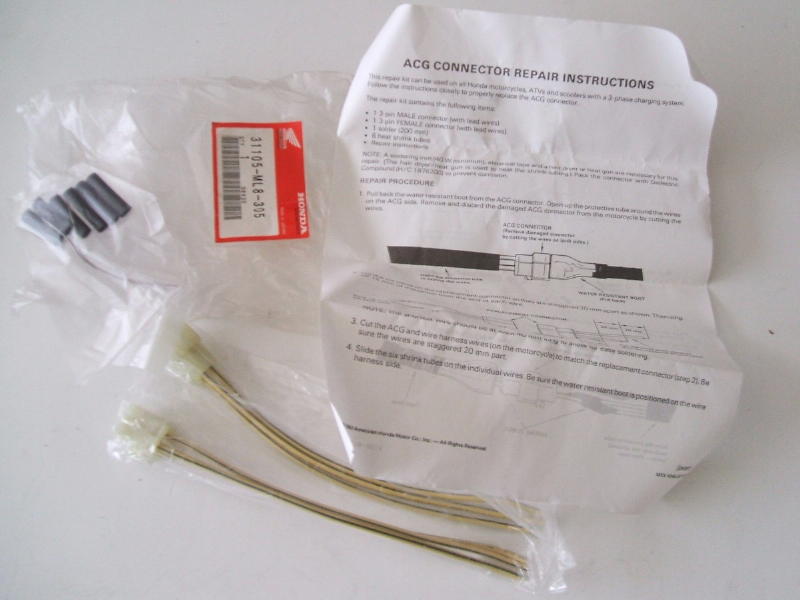

If there are problems, one time-honored and widely accepted repair is to

remove the connector entirely, solder the wires together, and cover with heat

shrink tubing. Alternately, Honda sells a connector repair kit (part number

31105-ML8-305) containing both connector halves and heat shrink tubing. In

either case, soldering is necessary. An excellent tutorial for solder-splicing

wires can be found

here.

Grounding Problems

Check the grounds. A poor or

intermittent ground connection can cause charging system problems including no

charging or charging voltage out of range, either high or low. The GL500 in

particular must have a good ground connection at this location under the seat

for proper charging system operation.

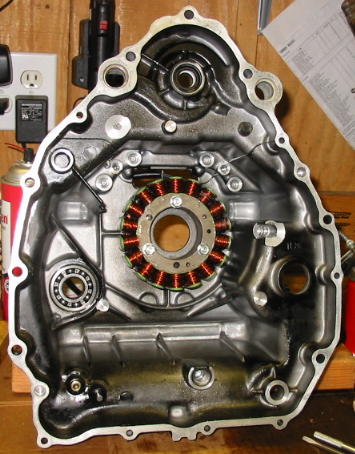

The Stator

Stator failures are fairly common. Unfortunately, the stator is located

inside the rear engine case. If replacement is necessary the engine must be

pulled and disassembled to gain access to the stator. Fortunately it is not

necessary to go to all this work to simply test the stator.

When testing the stator, multimeter measurements are taken at the stator connector with the connector unplugged.

Make sure you are taking measurements on the stator connector half that

goes to the engine, not the connector half that goes to the

regulator/rectifier. Tug on the wires to trace where they go - do not make a

false assumption about which end is which. A simple mistake in selecting the

wrong connector half could lead down an erroneous troubleshooting path so it is

important to confirm what is being measured.

Stator Resistance Checks

First, measure the resistance between each of the three stator connector terminal tabs and ground. Set the meter function switch to the highest resistance range possible (2000K in my case). The negative meter lead should be connected to the negative battery terminal. Measure each of the three stator connector terminal tabs in turn using the positive meter lead.

A good stator will have infinite resistance to ground (open circuit or no continuity) from any of these terminals. If the meter reads anything else, the stator is defective.

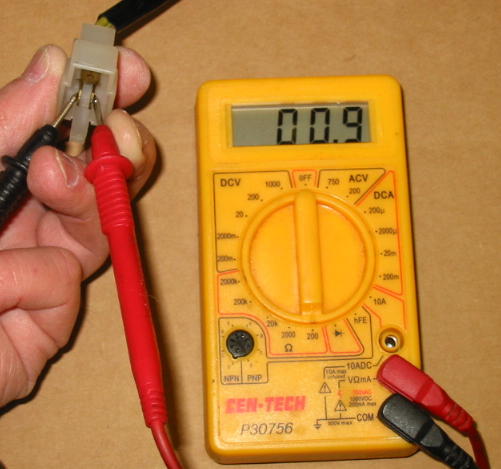

Next, measure the resistance between each of the three connector terminal

tabs. Set the meter function switch to the lowest resistance range possible

(200 in my case). In this case, the negative meter lead is not connected to the

negative battery terminal but is used to measure from one stator connector

terminal tab to the next with the positive meter lead as shown in this photo.

(This is the same photo seen earlier in the multimeter section.)

A good stator should measure well under one Ohm for each of the three possible test connections. As described in the multimeter section, be sure to consider the residual meter lead resistance when making this measurement - we are interested in the actual stator wire resistance, not that of the meter leads! If any of the three measurements are above 1.5 Ohms, the stator is defective.

Stator Voltage Checks

Assuming the stator resistance checks are good, the next thing to check is the stator open circuit voltage. The stator connector is also unplugged for this measurement. Set the meter to measure AC Voltage with a range selection of at least 100 Volts on your meter.

Start the bike and adjust the throttle so the engine is running at about 2000 rpm. Measure the AC Voltage between each of the three stator connector terminal tabs, tab-to-tab as in the previous resistance measurement (not tab-to-ground). Write down each of the three measured voltages.

The actual voltages measured are not so important, and they will vary with engine rpm over a range from about 40 Volts to 70 Volts. However, it is important that the three measured voltages are approximately the same value. A gross mismatch is a strong indication of a shorted stator winding.

A typical set of measurements for a good stator might be 53, 52, and 54 Volts. For a bad stator, this could be 18, 24, and 12 Volts. In the latter case the voltage is both grossly unbalanced and low.

A stator can pass the resistance checks but fail the voltage checks. In this case, one or more windings are shorted to themselves. Conversely, a stator can fail the resistance checks and pass the voltage checks. If the stator fails either set of checks it is defective.

Hot and Cold Stator Checks

The stator resistance and voltage tests should be performed both when the engine is cold and after it has warmed up to normal operating temperature. The stator windings can develop a short or open circuit as a function of temperature when they contract and expand. The tests are not complete until you've performed them under both conditions.

Stator Replacement

If you've positively determined that your stator is bad, there is a strong chance that nothing else has failed. That is the good news.

The bad news is that the engine must be pulled and disassembled to gain access to the stator. Since this is a significant task (although not really difficult), it makes sense to take care of other things within the engine that may also need attention while it is apart. The other big items are the cam chain and water pump mechanical seal, and the three together are often referred to as the "triple bypass operation." In addition, there are several seals and o-rings that should be replaced at the same time.

It is beyond the scope of this writeup to address all these items, but they are well documented on the Honda CX500 and GL500 Forum. In particular, check out the Quick Reference thread and the Triple Bypass Parts thread. You will also want to get a copy of the Honda factory service manual for your bike - don't even think of digging into your engine without it. A pdf copy can be downloaded for free from here. Should you have any questions, post a query on the Honda CX500 and GL500 Forum. The forum members will be eager to help.

There are several sources for replacement stators. More information can be found here.

The replacement stator will be provided with a new connector half, including the shell and terminal tabs. It should be the last thing installed after the engine has been replaced and the stator wires have been routed to the mating stator connector half. I recommend the new terminal tabs be both crimped and soldered. Unless you have the correct crimp tool it will be difficult to get a reliable connection otherwise. The last thing you want is arcing and related evils after the miles have accumulated and the wires work loose under vibration.

The original plastic connector shell has a locking tab to keep the connector halves secured together. Often the replacement connector shell is missing the locking tab. If this is the case, you may want to re-use your original connector shell if it is otherwise undamaged. The old terminal tabs can be easily removed by using a jeweler's screwdriver to press on their sides while gently pulling from the rear. Look closely at the new terminal tabs to see how they are secured in the connector shell.

The Regulator/Rectifier

The regulator/rectifier module performs two basic functions. It converts the

AC voltage from the stator to a DC voltage, and it regulates the resulting

voltage down to approximately 14.5 Volts as is needed by the rest of the

electrical system. GL regulator/rectifiers are mounted to the bottom of the

battery tray.

Honda CX/GL regulator/rectifiers are extremely reliable. I have no first-hand knowledge of one ever failing. Used ones are readily available on eBay for around $20, and given their reliability I would not hesitate to install a used one should the need ever arise.

The same cannot be said for aftermarket replacements, or even regulator/rectifiers used on other motorcycle models. Aftermarket replacement regulator/rectifiers cost around $100 new, but in general they have been found to be less reliable. One manufacturer in particular has a high percentage of defective units right out of the box.

The factory service manual and some aftermarket manuals describe procedures for testing the regulator/rectifier using multimeter resistance tests. It is my opinion that the results of these tests are unreliable and cannot be trusted. These test procedures were defined back in the days when multimeters were analog and had higher test voltages. A modern digital multimeter may or may not provide similar readings.

Perhaps the sole exception would be the case where a hard short (much less than an Ohm and reads the same no matter which way the meter leads are connected) is detected between the input and output. Failing this test would indicate a bad regulator/rectifier, but passing it would be inconclusive.

My recommendation is to simply replace the regulator/rectifier with a used Honda part as a last resort if all other charging system troubleshooting tests pass. It is very unlikely that your regulator/rectifier has failed. The probability of also having a defective Honda replacement part, even if it is well-used, is extremely remote.

If the other charging systems tests all pass, it is far more likely that there is a wiring problem.

Next Steps

The common charging system problems have been pretty much covered here. If you are still having problems with your CX/GL charging system, start a thread on the Honda CX500 and GL500 Forum and someone there (possibly me) will walk you through the troubleshooting process. Please do not ask for assistance directly via email; dialog on the forum is how the collective knowledge base grows and everyone benefits. Your tough problem will likely be experienced by someone else sometime in the future.

Multimeter Usage

Main Fuse and Grounding

Charging Problems

Ignition Problems

DC Voltage Testing

Resistance Tests

Wiring Fabrication and Repairs

Stray Topics